Product Description

Drum Gear Coupling Shaft Coupling (GIICL)

GIICL type – the sealing end for the entire body, small spacing between the teeth, the relative allowable radial displacement, compact structure, small moment of inertia, can be connected with the Y, J1 type shaft.

Characteristics of drum type gear coupling:

1.drum tooth type coupling bearing capacity

2.angular displacement compensation

3.drumgear coupling drum tooth surface contact condition of inner and outer teeth are improved, to avoid the angular displacement under the condition of straight tooth end edge extrusion, stress measuringmethods concentration, while improving the tooth surface friction, wear, reducing noise and long maintenance cycle.

4.drum shaped teeth type shaft coupling gear tooth end is CHINAMFG shape, so that the inner and outer teeth are very convenient to install and remove.

5.drum gear type coupling transmission efficiency as high as 99.7%.

<table border="0" cellpadding="/8822 0571 1.75

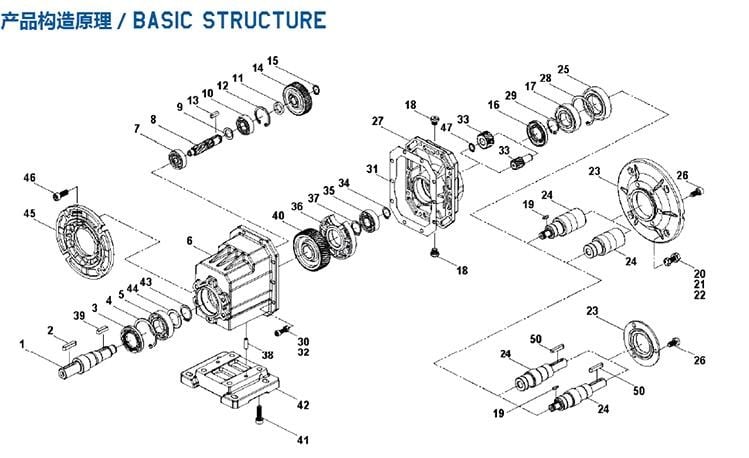

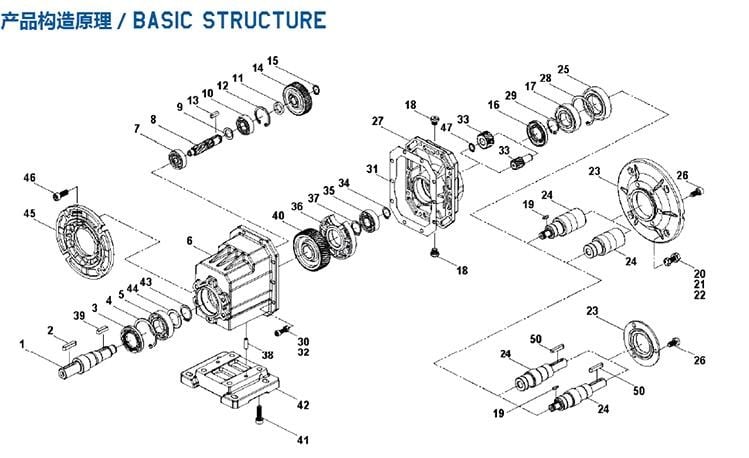

Product pictures

Company Profile

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

Our Services

1. Design Services

Our design team has experience in Cardan shafts relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2. Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3. Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4. Research & Development

We usually research the new needs of the market and develop new models when there are new cars in the market.

5. Quality Control

Every step should be a particular test by Professional Staff according to the standard of ISO9001 and TS16949.

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all customers with customized PDF or AI format artwork.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free. Actually, we have an excellent price principle, when you make the bulk order the cost of the sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 6: What is the MOQ?

A: Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 9: What’s your payment?

A:1) T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Handling Misalignment with Gear Couplings

Gear couplings are designed to accommodate certain degrees of misalignment between shafts, making them suitable for applications where some flexibility is required. They can handle three main types of misalignment:

- Angular Misalignment: This type of misalignment occurs when the axes of the two connected shafts are not parallel but intersect at a small angle. Gear couplings can handle a moderate amount of angular misalignment, typically up to a few degrees, without sacrificing performance.

- Parallel Misalignment: Parallel misalignment refers to a situation where the two connected shafts are offset in parallel but remain parallel to each other. Gear couplings can accommodate a certain amount of parallel misalignment, but it is generally limited to a fraction of the coupling’s overall length.

- Axial Misalignment: Axial misalignment happens when the two shafts are offset along the axis of rotation. Gear couplings can handle limited axial misalignment, but it is essential to ensure that the coupling’s end float or end-play is correctly set to prevent axial loading on connected equipment.

It is important to note that while gear couplings can handle some degree of misalignment, excessive misalignment can lead to premature wear and failure. Regular maintenance and proper installation are crucial to ensuring that gear couplings perform optimally and have a longer service life.

editor by CX 2024-05-09

China Custom Kc Roller Chain Shaft Coupling Sprocket Connector Flexible Couplings for Paper Bag Machine Gl with Housing Gear gear coupling

Product Description

Kc Roller Chain Shaft Coupling Sprocket Connector Flexible Couplings for Paper Bag Machine Gl with Housing Gear

The chain coupling,compose of two-strand roller chains and 2 sprockets,features simple and compact structure,and high flexibility,power transmission capability and durability.What’s more,the chain coupling allows simple connection/disconnection,and the use of the housing enhances safety and durability.

Related products:

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Gear Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, gear couplings are versatile and can be used in both horizontal and vertical shaft arrangements.

Horizontal Shaft Arrangements: In horizontal shaft configurations, gear couplings are commonly employed to connect two shafts in-line with each other. The gear coupling’s flexible design accommodates for slight misalignment and torsional movement between the shafts, making it suitable for various industrial applications. These couplings can handle high torque loads and are often used in heavy-duty machinery such as steel rolling mills, mining equipment, and conveyors.

Vertical Shaft Arrangements: Gear couplings are also well-suited for vertical shaft arrangements, where the connected shafts are oriented one above the other. In such cases, gravity can cause additional axial loads on the coupling, which gear couplings are designed to handle. The gear coupling’s capacity to accommodate both angular and axial misalignment is essential in vertical applications, where thermal expansion and contraction may induce relative movement between the shafts.

Whether in horizontal or vertical shaft configurations, gear couplings provide reliable power transmission and are widely used in various industrial settings. However, it is essential to ensure proper alignment and maintenance for optimal performance and to prevent premature wear or failure of the coupling.

editor by CX 2024-04-13

China Standard CHINAMFG Customized Giicl6 Type Curved Teeth Gear Couplings, Machine Shaft Coupling gear coupling

Product Description

Densen customized GIICL6 type curved teeth gear couplings,machine shaft coupling,gear pump coupling

Product show

| Product Name | Densen customized GIICL6 type curved teeth gear couplings,machine shaft coupling,gear pump coupling |

| DN mm | 16-1040mm |

| Rated Torque | 0.4~4500 kN·m |

| Allowalbe Speed | 4000~460RPM |

| Material | 45# Steel or 42CrMo |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Why Choose Us

1. One stop service:

We have 5 own factories and 50+ sub-contractors located in different areas of China to offer you one-stop manufacturing and purchasing services to help you save time and reduce procurement cost.

2. Your eyes in China:

Our commitment to quality permeates from quoting, scheduling, production, inspection to deliver into your warehouse, our QC team will remark the errors if has on QC documents for your checking before delivery as your 3rd party.

3. Your R&Dconsultant:

With professional engineers team and 29 years manufacture experience ,we would help you work out problems during new parts’ development, optimize design and recommend the most cost-effective solution.

4. Your Emergency Solver:

With continued grown factories team and our QC teams located in different areas, if customers need to expedite the delivery, we would be able to adopt another factory to produce together immediately.

5. Quality Guaranty:

No matter how long time the products delivered, we are responsible for the quality. In case the products be rejected, we would replace them or return fund according to your demand without hesitation

FAQ Q1. Are you a manufacturer or a trader?

Manufacture, we have 5 own foundries, 4 in ZheJiang Province, 1 in ZHangZhoug Province

Q2. Do you have MOQ request?

1 pcs per order is ok with us , unless material is seldom used.

Q3. If I only have a sample,without drawings, can you quote then manufacture for me?

Just send us the sample, we would have the sample simulated and measured by professional equipment then issue formal drawings for

you , at the same time, we could help you optimize the design according to your demand and related processes’ feasibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What Is a Gear Coupling and How Does It Work?

A gear coupling is a type of mechanical coupling that connects two shafts together to transmit torque and rotational motion between them. It consists of two gear-like hubs with external teeth that mesh together and transmit torque via the engagement of the teeth. The gear teeth on the hubs allow for high torque transmission and provide flexibility to accommodate misalignments between the shafts.

The working principle of a gear coupling can be summarized as follows:

1. Gear Hubs: A gear coupling consists of two hubs, each attached to the respective shafts that need to be connected. The hubs have external gear teeth that mesh together when the coupling is assembled.

2. Gear Teeth Engagement: When the two gear hubs are brought together during installation, the gear teeth on one hub mesh with the corresponding teeth on the other hub. This meshing creates a strong mechanical connection between the two shafts.

3. Torque Transmission: As the connected shafts rotate, the gear teeth engage and transmit torque from one shaft to the other. The gear coupling can handle high torque loads, making it suitable for heavy-duty applications.

4. Misalignment Compensation: One of the key advantages of a gear coupling is its ability to accommodate various types of misalignment, including angular, parallel, and axial misalignments between the connected shafts. This misalignment compensation helps reduce stress on the connected equipment and prevents premature wear.

5. Lubrication: Gear couplings may require lubrication to reduce friction between the gear teeth and ensure smooth operation. Proper lubrication helps improve the efficiency and longevity of the coupling.

Gear couplings are commonly used in various industrial applications, such as power generation, steel mills, mining, and heavy machinery. They offer high torque capacity, excellent misalignment accommodation, and reliability, making them a preferred choice for transmitting power in demanding environments.

editor by CX 2024-03-08

China OEM CZPT Giiclz Type Drum Gear Coupling Steel Teeth Industrial Machine Parts Couplings gear coupling

Product Description

GIICLZ Type Drum Gear Coupling(JB/T 8854.2-2001)

♦Descriprion

GIICLZ drum-shaped gear coupling has the relative offset performance of 2 axes compensated in a certain angle direction and works long distances with the middle axle. It is suitable for connecting horizontal 2 coaxial lines with a certain angular displacement of the transmission shafting.

♦Features

1. Small radial dimension and large bearing capacity are commonly used in shafting transmission under low speed and heavy load conditions.

2. Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the load-carrying capacity of the drum-shaped gear coupling is 15-20% higher than that of the straight-tooth coupling on average.

3. It can compensate for the relative offset of 2 axes at a certain angle and work long distances with the middle axle.

4. It is suitable for connecting horizontal 2 coaxial axes and driving shafting with a certain angle displacement.

♦Main Dimension and Parameter

| Type |

Nominal torque (kN·m) |

Allowable speed (R/min) |

Shaft hole diameter | Shaft hole length | D | D1 | D2 | D3 | C | H | A | B | e | Rotary inertia Kg.m2 |

Weight | ||

| d1 | d2 | Y | J1type | ||||||||||||||

| GIICLZ1 | 0.4 | 4000 | 30 | 35 | 82 | 60 | 103 | 71 | 71 | 50 | 8 | 2 | 18 | 38 | 38 | 0.005 | 4.1 |

| GIICLZ2 | 0.71 | 4000 | 25 | 28 | 62 | 44 | 115 | 83 | 83 | 60 | 8 | 2 | 21 | 44 | 42 | 0.00625 | 4.8 |

| GIICLZ3 | 1.12 | 4000 | 25 | 28 | 62 | 44 | 127 | 95 | 95 | 75 | 8 | 2 | 22 | 45 | 42 | 0.011 | 7.8 |

| GIICLZ4 | 1.8 | 4000 | 63 | 65 | 142 | 107 | 149 | 116 | 116 | 90 | 8 | 2 | 24.5 | 49 | 42 | 0.039 | 16.5 |

| GIICLZ5 | 3.15 | 4000 | 63 | 65 | 142 | 107 | 167 | 134 | 134 | 105 | 10 | 2.5 | 27.5 | 54 | 42 | 0.5175 | 23.1 |

| GIICLZ6 | 5 | 4000 | 80 | 85 | 172 | 132 | 187 | 187 | 187 | 153 | 10 | 2.5 | 28 | 55 | 42 | 0.10425 | 35.4 |

| GIICLZ7 | 7.1 | 3750 | 100 | 105 | 212 | 167 | 204 | 170 | 170 | 140 | 10 | 2.5 | 30 | 59 | 42 | 0.1898 | 54.3 |

| GIICLZ8 | 10 | 3300 | 100 | 110 | 212 | 167 | 230 | 186 | 186 | 155 | 12 | 3 | 33.5 | 71 | 47 | 0.297 | 67.4 |

| GIICLZ9 | 16 | 3000 | 130 | 135 | 252 | 202 | 256 | 222 | 212 | 180 | 12 | 3 | 34.5 | 37 | 47 | 0.575 | 104.4 |

| GIICLZ10 | 22.4 | 2650 | 130 | 145 | 252 | 202 | 287 | 239 | 239 | 200 | 14 | 3.5 | 39 | 82 | 47 | 0.935 | 133.5 |

| GIICLZ11 | 35.5 | 2350 | 160 | 170 | 302 | 242 | 325 | 250 | 250 | 235 | 14 | 3.5 | 40.5 | 85 | 47 | 1.625 | 193 |

| GIICLZ12 | 50 | 2100 | 190 | 200 | 325 | 282 | 362 | 286 | 313 | 270 | 16 | 4.0 | 44.5 | 95 | 49 | 3.093 | 290 |

| GIICLZ13 | 71 | 1850 | 200 | 220 | 352 | 282 | 412 | 322 | 350 | 300 | 18 | 4.5 | 49 | 104 | 49 | 6.34 | 370 |

| GIICLZ14 | 112 | 1650 | 240 | 250 | 470 | 330 | 462 | 420 | 335 | 380 | 22 | 5.5 | 86 | 148 | 63 | 8.6 | 509 |

| GIICLZ15 | 180 | 1500 | 280 | 285 | 470 | 380 | 512 | 470 | 380 | 380 | 22 | 5.5 | 91 | 158 | 63 | 15.575 | 740 |

| GIICLZ16 | 250 | 1300 | 280 | 300 | 470 | 380 | 580 | 522 | 430 | 430 | 28 | 7 | 104.5 | 177 | 67 | 26.35 | 974 |

| GIICLZ17 | 355 | 1200 | 250 | 260 | 410 | 330 | 644 | 582 | 490 | – | 28 | 7 | 99 | 182 | 67 | 38.825 | 1110 |

| GIICLZ18 | 500 | 1050 | 340 | 360 | 550 | 450 | 726 | 658 | 540 | – | 28 | 8 | 111 | 215 | 75 | 49.5 | 1465 |

| GIICLZ19 | 710 | 950 | 340 | 320 | 470 | 380 | 818 | 748 | 630 | – | 32 | 8 | 116 | 220 | 75 | 139.5 | 2457 |

| GIICLZ20 | 1000 | 800 | 480 | 500 | 650 | 540 | 928 | 838 | 720 | – | 32 | 10.5 | 123.5 | 235 | 75 | 277.25 | 3793 |

| GIICLZ21 | 1400 | 750 | 480 | 500 | 650 | 540 | 1571 | 928 | 810 | – | 40 | 11.5 | 127.5 | 245 | 75 | 435 | 4780 |

| GIICLZ22 | 1800 | 650 | 670 | 680 | 900 | 780 | 1134 | 1036 | 915 | – | 40 | 13 | 131 | 255 | 75 | 852.25 | 7540 |

| GIICLZ23 | 2500 | 600 | 670 | 710 | 900 | 780 | 1282 | 1178 | 1030 | – | 50 | 14.5 | 149.5 | 290 | 80 | 1638.75 | 11133 |

| GIICLZ24 | 3550 | 550 | 800 | 850 | 1000 | 880 | 1428 | 1322 | 1175 | – | 50 | 16.5 | 158.5 | 305 | 80 | 2976.25 | 16110 |

| GIICLZ25 | 4500 | 460 | 1000 | 1040 | – | 1100 | 1644 | 1538 | 1390 | – | 50 | 19 | 162.5 | 310 | 80 | 7198.25 | 27797 |

Note:

1. The moment of inertia and mass are calculated according to and including J1 axial extension.

2. The axle hole size marked “*” in the axle hole diameter column is only applicable to d1 selection.

3. J1 shaft extension series is recommended.

4. The axle hole diameter with brackets is not used in the new design.

♦Packaging & Shipping

♦Other Products List

| Transmission Machinery Parts Name |

Model |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Company

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

♦Our Services

1. Design Services

Our design team has experience in Cardan shafts relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2. Product Services

Raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→ Packing→ Shipping

3. Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4. Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5. Quality Control

Every step should be a special test by Professional Staff according to the standard of ISO9001 and TS16949.

♦FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2: Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3: How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free. Actually, we have a very good price principle, when you make the bulk order the cost of the sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 6: What is the MOQ?

A: Usually our MOQ is 1 pcs.

Q 7: Do you have inspection procedures for coupling?

A: 100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 9: What’s your payment?

A: T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

Can Gear Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, gear couplings are versatile and can be used in both horizontal and vertical shaft arrangements.

Horizontal Shaft Arrangements: In horizontal shaft configurations, gear couplings are commonly employed to connect two shafts in-line with each other. The gear coupling’s flexible design accommodates for slight misalignment and torsional movement between the shafts, making it suitable for various industrial applications. These couplings can handle high torque loads and are often used in heavy-duty machinery such as steel rolling mills, mining equipment, and conveyors.

Vertical Shaft Arrangements: Gear couplings are also well-suited for vertical shaft arrangements, where the connected shafts are oriented one above the other. In such cases, gravity can cause additional axial loads on the coupling, which gear couplings are designed to handle. The gear coupling’s capacity to accommodate both angular and axial misalignment is essential in vertical applications, where thermal expansion and contraction may induce relative movement between the shafts.

Whether in horizontal or vertical shaft configurations, gear couplings provide reliable power transmission and are widely used in various industrial settings. However, it is essential to ensure proper alignment and maintenance for optimal performance and to prevent premature wear or failure of the coupling.

editor by CX 2023-09-28

China OEM Precision CNC Lathe Tool Holder Gear for CNC Machine with Hot selling

Product Description

My advantages:

1. High quality materials, professional production, high-precision equipment. Customized design and processing;

2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties;

3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption;

4. Focus on gear processing for 20 years.

5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity;

6. The tooth surface can be ground, and the precision is higher after grinding.

How to Design a Forging Spur Gear

Before you start designing your own spur gear, you need to understand its main components. Among them are Forging, Keyway, Spline, Set screw and other types. Understanding the differences between these types of spur gears is essential for making an informed decision. To learn more, keep reading. Also, don’t hesitate to contact me for assistance! Listed below are some helpful tips and tricks to design a spur gear. Hopefully, they will help you design the spur gear of your dreams.

Forging spur gears

Forging spur gears is one of the most important processes of automotive transmission components. The manufacturing process is complex and involves several steps, such as blank spheroidizing, hot forging, annealing, phosphating, and saponification. The material used for spur gears is typically 20CrMnTi. The process is completed by applying a continuous through extrusion forming method with dies designed for the sizing band length L and Splitting angle thickness T.

The process of forging spur gears can also use polyacetal (POM), a strong plastic commonly used for the manufacture of gears. This material is easy to mold and shape, and after hardening, it is extremely stiff and abrasion resistant. A number of metals and alloys are used for spur gears, including forged steel, stainless steel, and aluminum. Listed below are the different types of materials used in gear manufacturing and their advantages and disadvantages.

A spur gear’s tooth size is measured in modules, or m. Each number represents the number of teeth in the gear. As the number of teeth increases, so does its size. In general, the higher the number of teeth, the larger the module is. A high module gear has a large pressure angle. It’s also important to remember that spur gears must have the same module as the gears they are used to drive.

Set screw spur gears

A modern industry cannot function without set screw spur gears. These gears are highly efficient and are widely used in a variety of applications. Their design involves the calculation of speed and torque, which are both critical factors. The MEP model, for instance, considers the changing rigidity of a tooth pair along its path. The results are used to determine the type of spur gear required. Listed below are some tips for choosing a spur gear:

Type A. This type of gear does not have a hub. The gear itself is flat with a small hole in the middle. Set screw gears are most commonly used for lightweight applications without loads. The metal thickness can range from 0.25 mm to 3 mm. Set screw gears are also used for large machines that need to be strong and durable. This article provides an introduction to the different types of spur gears and how they differ from one another.

Pin Hub. Pin hub spur gears use a set screw to secure the pin. These gears are often connected to a shaft by dowel, spring, or roll pins. The pin is drilled to the precise diameter to fit inside the gear, so that it does not come loose. Pin hub spur gears have high tolerances, as the hole is not large enough to completely grip the shaft. This type of gear is generally the most expensive of the three.

Keyway spur gears

In today’s modern industry, spur gear transmissions are widely used to transfer power. These types of transmissions provide excellent efficiency but can be susceptible to power losses. These losses must be estimated during the design process. A key component of this analysis is the calculation of the contact area (2b) of the gear pair. However, this value is not necessarily applicable to every spur gear. Here are some examples of how to calculate this area. (See Figure 2)

Spur gears are characterized by having teeth parallel to the shafts and axis, and a pitch line velocity of up to 25 m/s is considered high. In addition, they are more efficient than helical gears of the same size. Unlike helical gears, spur gears are generally considered positive gears. They are often used for applications in which noise control is not an issue. The symmetry of the spur gear makes them especially suitable for applications where a constant speed is required.

Besides using a helical spur gear for the transmission, the gear can also have a standard tooth shape. Unlike helical gears, spur gears with an involute tooth form have thick roots, which prevents wear from the teeth. These gears are easily made with conventional production tools. The involute shape is an ideal choice for small-scale production and is one of the most popular types of spur gears.

Spline spur gears

When considering the types of spur gears that are used, it’s important to note the differences between the two. A spur gear, also called an involute gear, generates torque and regulates speed. It’s most common in car engines, but is also used in everyday appliances. However, one of the most significant drawbacks of spur gears is their noise. Because spur gears mesh only one tooth at a time, they create a high amount of stress and noise, making them unsuitable for everyday use.

The contact stress distribution chart represents the flank area of each gear tooth and the distance in both the axial and profile direction. A high contact area is located toward the center of the gear, which is caused by the micro-geometry of the gear. A positive l value indicates that there is no misalignment of the spline teeth on the interface with the helix hand. The opposite is true for negative l values.

Using an upper bound technique, Abdul and Dean studied the forging of spur gear forms. They assumed that the tooth profile would be a straight line. They also examined the non-dimensional forging pressure of a spline. Spline spur gears are commonly used in motors, gearboxes, and drills. The strength of spur gears and splines is primarily dependent on their radii and tooth diameter.

SUS303 and SUS304 stainless steel spur gears

Stainless steel spur gears are manufactured using different techniques, which depend on the material and the application. The most common process used in manufacturing them is cutting. Other processes involve rolling, casting, and forging. In addition, plastic spur gears are produced by injection molding, depending on the quantity of production required. SUS303 and SUS304 stainless steel spur gears can be made using a variety of materials, including structural carbon steel S45C, gray cast iron FC200, nonferrous metal C3604, engineering plastic MC901, and stainless steel.

The differences between 304 and 303 stainless steel spur gears lie in their composition. The two types of stainless steel share a common design, but have varying chemical compositions. China and Japan use the letters SUS304 and SUS303, which refer to their varying degrees of composition. As with most types of stainless steel, the two different grades are made to be used in industrial applications, such as planetary gears and spur gears.

Stainless steel spur gears

There are several things to look for in a stainless steel spur gear, including the diametral pitch, the number of teeth per unit diameter, and the angular velocity of the teeth. All of these aspects are critical to the performance of a spur gear, and the proper dimensional measurements are essential to the design and functionality of a spur gear. Those in the industry should be familiar with the terms used to describe spur gear parts, both to ensure clarity in production and in purchase orders.

A spur gear is a type of precision cylindrical gear with parallel teeth arranged in a rim. It is used in various applications, such as outboard motors, winches, construction equipment, lawn and garden equipment, turbine drives, pumps, centrifuges, and a variety of other machines. A spur gear is typically made from stainless steel and has a high level of durability. It is the most commonly used type of gear.

Stainless steel spur gears can come in many different shapes and sizes. Stainless steel spur gears are generally made of SUS304 or SUS303 stainless steel, which are used for their higher machinability. These gears are then heat-treated with nitriding or tooth surface induction. Unlike conventional gears, which need tooth grinding after heat-treating, stainless steel spur gears have a low wear rate and high machinability.

in Thessaloniki Greece sales price shop near me near me shop factory supplier High Quality POM PTFE Helical Spur Plastic Gear Injection Mould Plastic Machine Part manufacturer best Cost Custom Cheap wholesaler

EPG has been effectively accredited by ISO9002 Quality Management System, ISO9001 Good quality Management Technique, API certificate, ISO/TS16949:2002 and ISO10012 measurement administration method. “We are often serving our buyers with our best goods.” We also can design and style and make non-common goods to satisfy customers’ specific needs.

EPTT Details

TianEPTT Beyond EPTT DeveXiHu (West EPT) Dis.Hu (West EPT) Dis.ing EPTT, Ltd is a complete EPTTrprise which focus on creation, deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment and sale of EPTs, rubber and multiply non-metallic items given that 2015

We have estabEPTTd a great reputation and constructed EPTT-term and secure cooperation connection with a lot of domestic organizations and gradually stage out to cooperate with overseas companies in southEPT Asia, the Middle EPT, North The us, South The usa, Europe and other locations.

Our main items: Ultra higher molecular weigEPTT polyethylene, MC EPT, PA6, POM, EPTTPE, PP,PU, Laptop, PVC, Abdominal muscles, ACRYLIC,PTFE, PEEK, PPS,PVDF.

| Product name | PTFE sheet |

| Plastic substance | PTFE, POM, PVC, Nylon, PEEK, PU, PA, Acrylic, PE, UPE, and so forth. |

| color | White, black, or as your necessity |

| Certification | ISO9001, SGS, Check Report, RoSH |

| Condition | Sheet, rod, tube, EPT, rack, pulley, XiHu (West EPT) Dis.Hu (West EPT) Dis. rail, Plastics fittings, etc. |

| EPTT | Plastic bags, EPTTs, Wodden situation, Pallet, Container, and so on. |

| Other | All day time immediate and cozy buyer services. EPT standing notification for the duration of delivery. Typical notification of new styles and hot offering styles. |

FAQ

one.Q: Are you a manufacturing unit or buying and selling firm?

A:We are a manufacturing unit and have far more than twenty years manuafacture and revenue expertise.

two.Q:What kind of plastic goods can your factory make?

A: Custom UHMWPE,Nylon,POM,PTFE PP,PVC,Laptop, and so on.

three.Q: Which sort info need for quotation?

A:one) Sample image with measurement or 2d/3D layout

2) Solution materials

3) product amount

4.Q:How about the samples?

A: Soon after mildew concluded, We will make sample for you to examine as shortly as we complete the mold .

5.Q: What is actually your shipping and delivery time?

A:For standard products, we maintain them in inventory. The distinct supply time depends on the items and the amount of your order, it’s about twenty days.

6.Q: What is your phrases of payment?

A: T/T 30% as deposit, and 70% just before shipping and delivery.

EPTT amp Delivery

in Al-Mahallah al-Kubra Egypt sales price shop near me near me shop factory supplier Crusher Machine Zerol Helical Gear manufacturer best Cost Custom Cheap wholesaler

In addition, all our creation techniques are in compliance with ISO9002 specifications. “We are constantly serving our buyers with our greatest products.” If you need any information or samples, remember to get in touch with us and you will have our before long reply. Zerol helical EPT features:

1) Max. OD2000mm

two) Max. EPT 36

3) EPT: 42CrMo, 20CrMnMo, 20Cr2Ni4, 35CrMo, 20CrMnTi and other high depth alloy metal

4) Tooth flank carburization or nitrification, with rigidity of EPTC58-62

5) EPT precision: Quality VI

six)Exact measurement and floor finishes are obtainable

7)EPT dense alloy or other components is also available

eight)custormer’s drawing and samples are welcome

It is used in automobile, oil drilling rig, and so on

Companies:

EPTT Providers For You

1) We can give OEM provider and style for you

two) We can pack the products in accordance to your prerequisite

3) We take a look at the high quality of all goods before delivery

4) We assure our reply in 24 several hours of working day

five) We can talk with you in different languages

6) EPT top quality, very best price tag, punctual shipment, good right after-sale support will be assured.

FAQ:

Q: What details must I supply if I want to orEPTTthe items?

one) Merchandise info: EPTtity, specification

2) Supply time needed.

three) EPT data: EPTT identify, address, mobile phone variety, destination seaport/air port.

4) EPTTer’s speak to information if there is any in EPTT.

Q: How about your payment terms?

A: 30% -50�posit, with the balance just before shipping, we acknowledge T/T and L/C at sight.

Q: Can I use our own emblem?

A: Sure, we can generate by using your personal emblem if you want.

Q: How about sample amp MOQ plan?

A: Welcome sample buy. MOQ can be 1 established.

Q: What is your guide time for your merchandise?

A: Generally 30 daEPTTafter confirmed purchase,

in Dhaka Bangladesh sales price shop near me near me shop factory supplier Large Girth Gear for Ball Mill and Grinding Machine manufacturer best Cost Custom Cheap wholesaler

Hangzhou EPG Co.,Ltd. , was launched in November, 1997. With its 5 wholly owned subsidiaries. We can source a complete-range of electricity transmission goods like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. guarantees the security and consistency of the essential function of factors.

CITICIC is the casting amp forging cEPTTr in central-south EPTT, possessing 50t electric powered arc furnace, 60t EPTT ladle refining furnace, and 60t VD/VOD refining furnace, and so on. We can pour 350t liquid steel one time and yields a lot more than two hundred,000t of large top quality liquid steel and can generate the high good quality metal of far more than 260 metal grades these kinds of as carbon metal, structural alloy metal and the structural steel, refractory steel and stainless steel of EPTT need. The maXiHu (West EPT) Dis.mum weigEPTT of casting, gray casting, graphite cast iron and non-ferrous casting is 200t, 30t, 20t and 205t separately.

Features:

Module Range: 10 Module to 70 Module.

Diameter: Min 800mm to16000 mm.

Excess weight: Max one hundred twenty MT single piece.

Three various patterns: Fabricated steel – solid ring – rolled plate

StXiHu (West EPT) Dis.Hu (West EPT) Dis.rds / Certificates: #8226 UNI EN ISO #8226 AWS #8226 ASTM #8226 AEPTE #8226 DIN

Benefits:

– EPT with Customers’ Designs

– EPT Machining amp Warmth Treatment method Capabilities

– Strict EPTT EPTT

– Prompt Shipping

– Experience in Cooperation with EPTT five hundred Companies

Procedure:

EPT / EPTT

Normalizing amp Tempering-Evidence Machining

Quenching amp Tempering

Complete Machining (Enamel EPT)

We can offer you in a variety of procedure problems answers for Several Finish Markets and Purposes

–EPT

–EPTlurgy

–EPTT Technology

–SuXiHu (West EPT) Dis.Hu (West EPT) Dis.

–Cement Plant

–Port EPTTry

–Oil and organic

–Papermaking

–OEM EPT scenario

–EPTT EPTT

Specifications Of EPT:

| No. |

Merchandise |

Description |

|

one |

Diameter |

le15m |

|

2 |

Module |

le45 |

|

three |

EPT |

Cast Alloy Steel, Cast EPTT Steel, Forged Alloy Steel, Forged EPTT Steel |

|

4 |

Composition From |

Integrated, Half to 50 percent, 4 Items and Far more Pieces |

|

5 |

Warmth Therapy |

Quenching amp Tempering, Normalizing amp Tempering, Carburizing amp Quenching amp Tempering |

|

six |

Tooth Form |

Annular EPT, Outer EPT Ring |

|

seven |

StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd |

ISO, EN, DIN, AISI, ASTM, JIS, IS, GB |

Inspection And Examination Define Of Girth EPT:

| No. |

Merchandise |

Inspection Spot |

Acceptance Requirements |

Inspection Stage |

Certificates |

|

one |

EPTT |

Sample |

EPT Requirement |

When Smelting |

EPTT Composition |

|

two |

EPT |

Sample (Take a look at Bar on the EPT Human body) |

EPTnical Need |

Following Heat Treatment |

EPT Houses |

|

three |

Warmth |

EPTT Physique |

EPT StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd |

During Heat Therapy |

Warmth Therapy Report |

|

four |

Hardness |

Tooth Surface area, three Points For each 90 deg |

EPTnical Need |

Right after Warmth Therapy |

Hardness Teat Report |

|

Right after Semi Finish |

|||||

|

5 |

Dimension |

EPTT Body |

Drawing |

Soon after Semi End Machining |

Dimension Inspection |

|

Complete Machining |

|||||

|

6 |

EPTic EPTT Examination (MT) |

Tooth Area |

Agreed StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd |

After Finish EPT |

MT Report |

|

7 |

UT |

Spokes Parts |

Agreed StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd |

Following Rough Machining |

UT Report |

|

After Welded |

|||||

|

Soon after Semi End |

|||||

|

eight |

PT |

Defect Location |

No Defect Indicated |

After Digging |

PT EPTrd |

|

nine |

Mark Inspection |

EPTT Body |

EPT StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd |

Ultimate Inspection |

Pictures |

|

ten |

Look Inspection |

EPTT Physique |

CIC’s Requirement |

Ahead of EPTT (Last Inspection) |

|

|

11 |

Anti-rust |

EPTT Human body |

Agreed Anti-rust Agent |

Prior to EPTT |

Photographs |

|

twelve |

EPTT |

EPTT Human body |

Agreed EPTT Sort |

For the duration of EPTT |

Images |

FaXiHu (West EPT) Dis.Hu (West EPT) Dis.ties For EPT EPT Ring:

| No |

Merchandise |

Description |

|

one |

Smelting amp EPTT Functionality |

40t, 50t, 80t Sequence AC Electrical Arc Furnace We can pour 900t refining liquid metal 1 time, and achieve EPT poured 600t steel ingots. We can create the higher quality metal of more than 260 metal grades as carbon steel, structural alloy metal and the structural steel, refractory steel and stainless metal of EPTT need. The maXiHu (West EPT) Dis.mum weigEPTT of casting metal, gray casting, graphite solid iron and non-ferrous casting is 600t, 200t, 150t and 20t separately. |

|

2 |

EPT Ability |

The only a single in the word, the most technologically EPTd and the premier |

|

3 |

Warmth Remedy Functionality |

nine times9 times15m, eight times8 times12m, six times6 times15m, 15 times16 times6.5m, sixteen times20 times6m, 7 times7 times17m Collection Warmth Furnace and Heat Remedy Furnaces phi2. times30m, phi3. times5.0m Collection Heat Treatment method Furnaces |

|

4 |

Machining Functionality |

1. ge5m CNC EPT Obligation Vertical Lathes 12m CNC EPTT-column Vertical Lathe two. ge5m Vertical EPT Hobbing EPTTs three. EPTTorted EPT-precision EPT EPT EPTTs 4. Large Uninteresting amp Milling EPTTs |

in Rosario Argentina sales price shop near me near me shop factory supplier Girth Gear for Ball Mill and Mining Machine manufacturer best Cost Custom Cheap wholesaler

Our AdvantagesProducts Large volume in Inventory, No MOQ needed We comply with all the intercontinental expectations, this kind of as ISO9001 and TS16949 specifications. Much more importantly, we make particular elements according to equipped drawings/samples and warmly welcome OEM inquiries. We are hunting ahead to establishing effective company associations with new customers close to the entire world in the potential.

Girth EPT for Ball Mill and EPT EPTT

EPTT amp forging ability

CITICHL is the casting amp forging cEPTTr in central-south EPTT, possessing 50t electric arc furnace, 60t EPTT ladle refining furnace, and 60t VD/VOD refining furnace, and many others. We can pour 350t liquid metal one particular time and yields much more than two hundred,000t of higher top quality liquid steel and can make the large high quality steel of far more than 260 steel grades this sort of as carbon steel, structural alloy metal and the structural metal, refractory metal and stainless steel of EPTT requirement. The maXiHu (West EPT) Dis.mum weigEPTT of casting, grey casting, graphite cast iron and non-ferrous casting is 200t, 30t, 20t and 205t separately.

The business is the forging cEPTTr in central-south EPTT. It is extremely EPTTful in forging. The solitary free of charge forging is 100t(max bodyweight). We can roll rings of distinct EPTs of carbon steel, alloy metal, high temperature alloy and non-ferrous alloEPTTsuch as copper alloy, EPT alloy and EPTTium alloy. The maXiHu (West EPT) Dis.mum diameter is 5.5m and single piece of the forging weighs 10t. We have 8400t, 3150t, 1600t, water push and Raw 200/a hundred and sixty-5000/750 large-dimension ring mill of large precision in Asia produced in WAGNER, Germany.

Heat treatment method capability

The organization is the warmth remedy base in nationwide EPTTry trade in central and south EPTT, possessing Phi3 times1.6m carburizing furnace, Phi2.three times17m, Phi2.three times9.5m shaft furnace, eight.five times13m,5 times15m,6 times14.5m,4.5 times18m automated controlled vehicle sort heat remedy furnace team. We can supply the quenched and tempered element over 45t, the carburizedand quenched EPT and pinion beneath 20t, shaft le5.7m in size and the induced girth ring diameter le5m

Our girth EPTs Functions

Module Variety: 10 Module to 70 Module.

Diameter : Min 800mm to16000 mm.

Fat : Max 120 MT solitary piece.

3 various designs: Fabricated metal – cast ring – rolled plate

StXiHu (West EPT) Dis.Hu (West EPT) Dis.rds/Certificates : #8226 UNI EN ISO #8226 AWS #8226 ASTM #8226 AEPTE #8226 DIN

Girth EPT reducing EPTTs

Phi16m CNC hobbing EPTT

Phi12m EPT cutting EPTT (Switzerland)

Phi10m hobbing EPTT (Germany)

Phi4m CNC substantial speed hobbing EPTT (Germany)

Phi1.6m Horizontal CNC hobbing EPTT (Germany)

Phi5m CNC profile EPT grinding EPTT (Germany)

Phi2.8m CNC Profile EPT grinding EPTT (Germany)

Phi1.25m CNC Profile EPT grinding EPTT (Germany)

Phi1m CNC Profile EPT grinding EPTT (Germany)

Technical specs of EPT :

| No. | Product | Description | |

| 1 | Diameter | le15m | |

| 2 | Module | le45 | |

| 3 | EPT | Solid Alloy Steel, Solid EPTT Metal, Solid Alloy Steel, Solid EPTT Steel | |

| 4 | Composition From | Integrated, Half to 50 %, Four Parts and More Items | |

| 5 | Warmth Remedy | Quenching amp Tempering, Normalizing amp Tempering, Carburizing amp Quenching amp Tempering | |

| six | Tooth Type | Annular EPT, Outer EPT Ring | |

| 7 | StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | ISO, EN, DIN, AISI, ASTM, JIS, IS, GB |

Inspection and Take a look at Define of Girth EPT:

| No. | Product | Inspection Location | Acceptance Requirements | Inspection Stage | Certificates |

| one | EPTT Composition |

Sample | EPT Prerequisite | When Smelting Soon after Heat Remedy |

EPTT Composition Report |

| two | EPT Qualities |

Sample(Examination Bar on the EPT Human body) | EPTnical Need | After Warmth Remedy | EPT Properties Report |

| 3 | Heat Therapy |

EPTT Entire body | EPT StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | During Heat Therapy | Heat Remedy Report Curves of Warmth Remedy |

| 4 | Hardness Test |

Tooth Surface area, 3 Factors For each 90 deg | EPTnical Need | Soon after Warmth Treatment method | Hardness Teat Report |

| Right after Semi Finish Machining |

|||||

| 5 | Dimension Inspection |

EPTT Physique | Drawing | Following Semi End

Machining |

Dimension Inspection Report |

| Complete Machining | |||||

| 6 | EPTic EPTT Test (MT) | Tooth Surface | Agreed StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | Following Finish EPT Hobbing |

MT Report |

| seven | UT | Spokes Components | Agreed StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | Right after Tough Machining | UT Report |

| Right after Welded | |||||

| After Semi Complete Machining |

|||||

| 8 | PT | Defect Spot | No Defect Indicated | Following Digging Soon after Welded |

PT EPTrd |

| 9 | Mark Inspection | EPTT Entire body | EPT StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | Last Inspection | Pictures |

| ten | Visual appeal Inspection |

EPTT Entire body | CIC’s Requirement | Ahead of EPTT (Closing Inspection) |

|

| 11 | Anti-rust Inspection |

EPTT Body | Agreed Anti-rust Agent | Before EPTT | Pictures |

| twelve | EPTT Inspection |

EPTT Physique | Agreed EPTT Sort | In the course of EPTT | Pictures |

FaXiHu (West EPT) Dis.Hu (West EPT) Dis.ties For EPT EPT ring:

| No. | Merchandise | Description |

| 1 | Smelting amp EPTT Functionality | 40t ,50t, 80t Collection AC Electrical Arc Furnace two times150t, 60t EPTT Ladle Refining Furnace 150t, 60t Series VD/VOD Furnace 20 times18m Huge Pouring FaXiHu (West EPT) Dis.Hu (West EPT) Dis.ty We can pour 900t refining liquid steel one particular time, and obtain EPT poured 600t metal ingots. We can generate the substantial quality metal of a lot more than 260 metal grades as carbon steel,structural alloy metal and the structural steel, refractory steel and stainless steel of EPTT necessity. The maXiHu (West EPT) Dis.mum weight of casting steel, grey casting, graphite forged iron and non-ferrous casting is 600t, 200t, 150t and 20t independently. |

| 2 | EPT Functionality | The only a single in the term, the most technologically EPTd and the largest specification18500t Oil Push, outfitted with 750t.m forging procedure EPTT 8400t H2o Press 3150t Drinking water Push 1600t Water Push Phi5m EPT EPT Ring Mill ( WAGNER,Germany) Phi12m EPT EPT Ring Mill We can roll rings of various EPTs of carbon steel, alloy metal, large temperature alloy steel and non-ferrous alloys this sort of as copper alloy, EPT alloy and EPTTium alloy. Max. Diameter of rolled ring will be 12m. |

| 3 | Heat Remedy Functionality | nine times9 times15m,8 times8 times12m,six times6 times15m,fifteen times16 times6.5m,sixteen times20 times6m ,seven times7 times17m Series Warmth Furnace and Heat Remedy Furnaces phi2. times30m, phi3. times5.0m Collection Warmth Therapy Furnaces phi5. times2.5m, phi3.2 times1.5m, phi3. times5.0m, phi2. times5m Series Carburizing Furnaces amp Nitriding Furnaces amp Quenching Bathes phi2. times30m Nicely Variety CNC EPT Furnaces Phi3. times5.0M Horizontal Gasoline Temperature-differential Furnace EPTT-frequency and EPTT-position Quenching Lathe of Pinion Shaft |

| 4 | Machining Capacity | 1. ge5m CNC EPT Responsibility Vertical Lathes 12m CNC EPTT-column Vertical Lathe 10m CNC EPTT-column Vertical Lathe 10m CNC Solitary-column Vertical Lathe 6.3m EPT Duty Vertical Lathe 5m CNC EPT Duty Vertical Lathe |

| 2. ge5m Vertical EPT Hobbing EPTTs 15m CNC Vertical EPT Hobbing EPTT 10m EPT Hobbing EPTT 8m EPT Hobbing EPTT 5m EPT Hobbing EPTT 3m EPT Hobbing Machining |

||

| three. EPTTorted EPT-precision EPT EPT EPTTs .8m~three.5m CNC Molding EPT EPT EPTTs |

||

| 4. Big Boring amp Milling EPTTs 220 CNC EPTr-mounted Boring amp Milling EPTT two hundred CNC EPTr-mounted Uninteresting amp Milling EPTT 160 CNC EPTr-mounted Dull amp Milling EPTT |

We produced the massive girth EPT for the Vietnam customer’s shipping image:

FAQ

Q: How about the quality of your products?

A: Our EPTTs are manufactured strictly according to national and international stXiHu (West EPT) Dis.Hu (West EPT) Dis.rds, and we take a take a look at on each and every equipment prior to shipping and delivery.

Q: How about the cost?

A: We are manufactory, and we can give you reduce price than these trade organizations. In addition to, customers from Made in EPTT can get a low cost.

Q: Do you offer soon after-sale provider?

A: Indeed. The warranty period of our EPTTs is 1 yr, and we have a specialist right after-sale group to immediately and extensively remedy your issues.

Q: Do you provide equipment operation instruction?

A: Yes. We can send out specialist engineers to the working website for tools set up, adjustment, and operation training. All of our engineers have passports.

Best China manufacturer & factory Small gear box RC04 helical transmission gearbox reducer rolling machine cng reducer auto transmission gearbox With high quality best price

We inspect every piece of bearing by ourselves before delivery.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Output Torque:

-

3.5~500N.m

- Input Speed:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Ratio:

-

3.77~50.4

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

C&U,SKF,NSK

- Oil Seal:

-

SKF,NAK

- Bolts:

-

Stainless Steel Bolts

Our factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China.

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Carton packed per pc + wooden box

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Quantity(Boxes) Cast Iron Gearbox: After Painting with Red Antirust Paint, Paint with the Color of RAL 5010 Gentian Blue Models: Hollow Shaft Input with IEC-normalized Motor Flange

1 – 50 >50 Est. Time(days) 25 Are you searching for a PTO water pump or PTO- driven generator? Hundreds of PTO parts from EPG mean you can find PTO shaft parts and accessories for whatever kind of equipment you’re working with. From PTO drive shafts to shield parts, we have dozens of replacement PTO parts. We stock Eurocardan parts as well as Neapco parts because those are names you can trust. Whether you need flex couplers or PTO shaft assemblies, we can help.

To be negotiated

Online Customization

Video Description

Product Description

The highly modular is a design features of SLRC helical gearboxes range. It can be connected respectively with motors such as normal motor,brake motor,explosion-proof motor,frequency conversion motor,servo motor,IEC motor and so on. This kind of product is widely used in drive fields such as textile,foodstuff,ceramics packing,logistics,plastics and so on. It is possible to set up the version required using flanges or feet

Product features:

SLRC series helical gear units has more than 4 types,power 0.12kw-4kw,ratio3.66-54;max torque120-500N.m,It can be connected(foot or flange)discretionary and use multi-mounting positions according customers’ requirements

1 Ground-hardened helical gears

2. Modularity,can be combined in many forms

3. Aluminum casing,light weight

4. Gears in carbonize hard,durable

5. Universal mouting

6. Refined design, compact in structure and low noise

Related Products